Temp-Plate Inflated Heat Transfer Surfaces

Paul Mueller Company

Type: Heating & Heat Transfer

Manufacturer: Paul Mueller Company

Product Description

Paul Mueller Temp-Plate heat exchangers are used to provide direct heating or cooling including heat recovery in a variety of processes in the food processing, carpet & textile, plating & anodizing, aerospace, chemical and industrial markets. Typical heat transfer mediums used are water, glycol, oil, and steam.

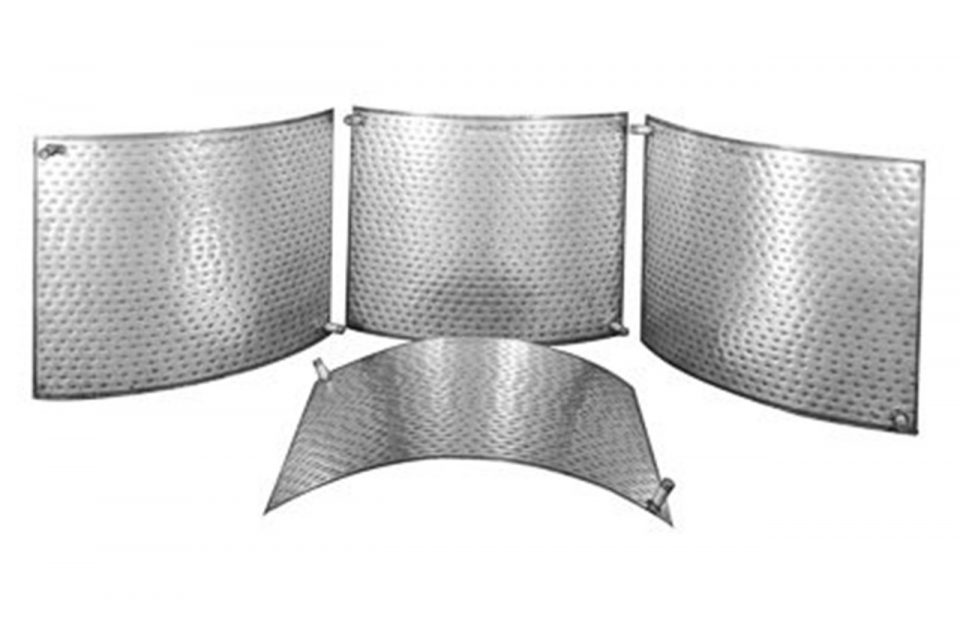

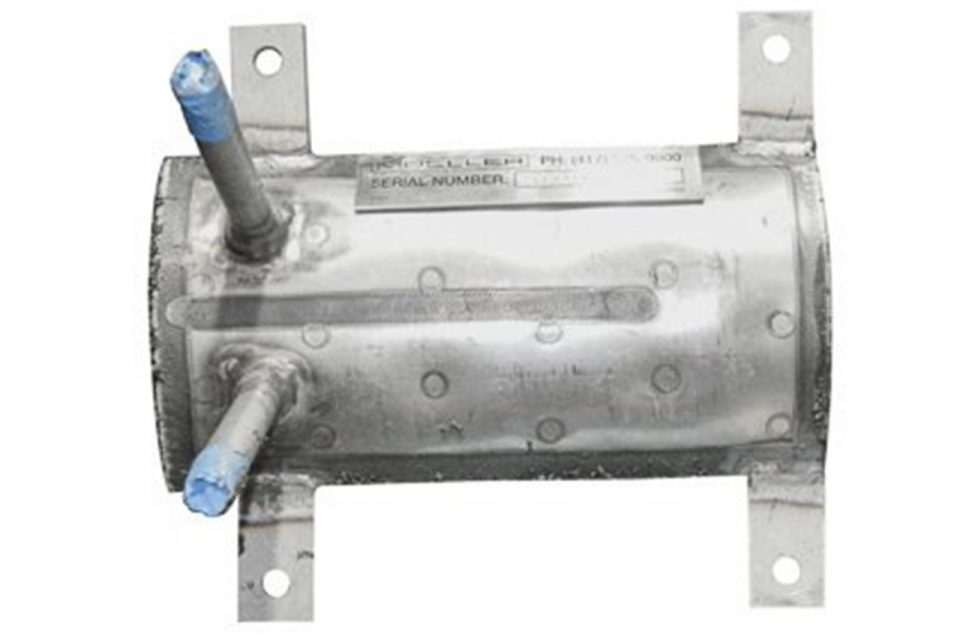

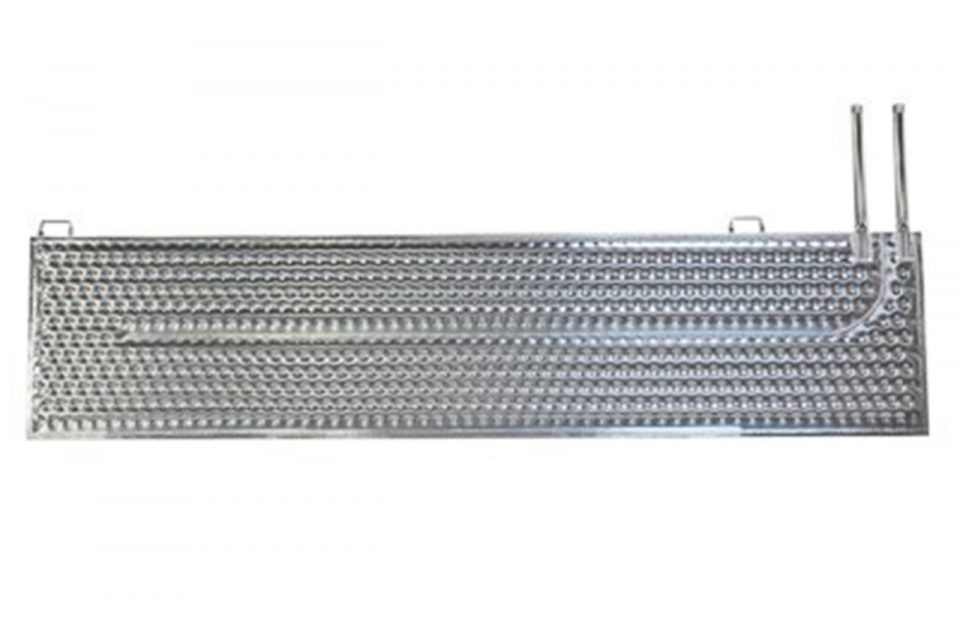

A Temp-Plate heat exchanger consists of two sheets of metal, typically stainless steel but also available in titanium Grade-1, carbon steel or high alloy metals that are spot welded every few inches across the sheets and seam welded around the edges creating a single panel. The panel is inflated to create a continuous space for the flow of a heating or cooling medium.

The Temp-Plate panels can be manufactured for use as immersion heaters, clamp-on panels, or built as integral units (panels assembled to create a vessel, tank, hopper or custom equipment). Temp-Plate can be designed and built to meet your exact needs with irregular shapes suitable for high pressures or corrosive environments.

Temp-Plate panels are an excellent alternative to shell and tube, pipe coil, and electric immersion heaters. Temp-Plate panels require significantly less space than shell and tube technology and minimize the chances of fouling. Only your imagination can limit the use of Temp-Plate heat exchanger technology.